|

More than 80 Years of Press Building Experience

Blow Press of Ontario, Canada is a leading

specialist maker of high-quality mechanical presses for medium to large-scale

stamping operations. GW Technologies is the Australasian agent for Blow Press,

representing Blow's range of straight-sided presses and single- and double-crank

gap frame presses, ranging from 39tons to 3000 tons. Blow offers presses

customised to suit your particular needs.

All Blow presses are constructed of heavily

reinforced steel weldments. Piping, wiring and controls may be mounted

externally or built into frame members. All transmission shafting and gearing is

designed for infinite life under fatigue loading.

BLOW Gap-Frame Presses:

Press frames are constructed from heavily

reinforced 1020 steel and fully stress-relieved and crankshafts are machined

from a 1045 steel forging, giving these presses low deflection and extremely

high rigidity for long service life for your presses and dies. 6-point gibbing

guarantees precision through the press stroke.

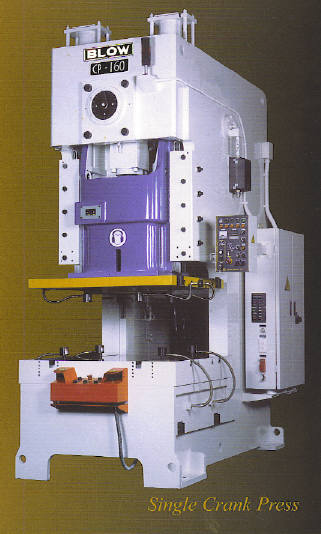

Single-Crank Gap Frame presses

|

Standard Features:

-

Motorised slide adjustment

-

Hydraulic overload protection

-

Safety Die Block

-

6-point square gibbing

-

Recirculating auto lubrication

-

Outlinghaus Clutch/Brake

-

Preset counter

-

Variable-speed AC Drive

-

JIC T-slots in bolster and slide

-

Capacity 39 to 276 U.S. Tons

-

Shut Height 9.9" to 21.7"

-

Stroke length 2.8" to 9.8"

Options:

-

Die Cushion

-

Vibro-Mounts

-

Quick Die Change

-

Feed Systems

-

Slide Knockout

|

|

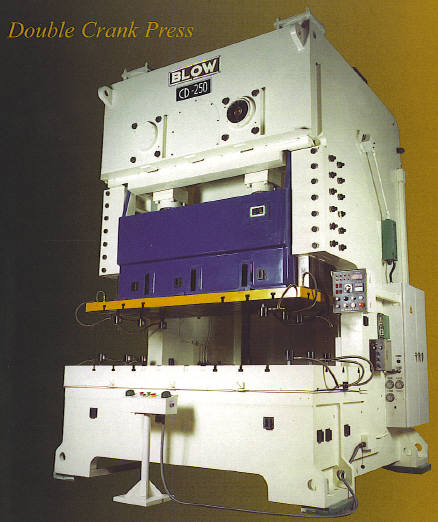

Double-Crank Gap Frame presses

|

Standard Features:

-

Motorised slide adjustment

-

Hydraulic overload protection

-

Safety die block

-

6-point square gibbing

-

Recirculating auto lubrication

-

Outlinghaus clutch/brake

-

Preset counter

-

Variable-speed AC Drive

-

JIC T-slots in bolster and slide

-

Capacity 88 to 276 U.S. Tons

-

Shut height 13.8" to 21.6"

-

Stroke length 5.5" to 11"

Options:

-

Die cushion

-

Vibro-mounts

-

Quick die change

-

Slide knockout

|

BLOW SC2 Straight-Sided Presses

Capacities 150 to 1000 U.S. tons

|

Standard Features:

-

Four piece pre-stressed tie-rod

construction

-

1-piece forged steel crankshaft

-

Bed and slide deflection - 0.0017"

per foot

-

Twin-end drive rated 1/2" above

stroke bottom

-

Single-end drive rated 1/4" above

stroke bottom

-

Full eccentric shaft up to 14" stroke

available at no extra cost

-

Recirculating oil lubrication with

flow monitor

-

Hydraulic tie-rod ends with pump

-

Oil-immersed main gearing

-

8-point fully adjustable gibbing

-

JIC T-slotting in slide and bolster

-

Solid-state clutch/brake control and

PLS

-

Press or floor-mounted electrics

-

Floor-mounted operator stand

-

Stroke 6" to 22"

-

Shut height 18"-40"

Options:

-

Hydraulic overload protection with

1.5msec response time

-

Bed and slide deflection .0005"

per foot

-

Oversized flywheel and drive for

high-energy applications

-

Pneumatic die cushion - internal or

external guiding

-

Variable speed drives (brushless DC

or adjustable frequency AC)

-

Hydraulic clutch/brake combination

-

Automation control and die protection

-

Rolling bolsters - straight track or

bi-directional

-

QDC systems

-

Custom bed sizes and heights

|

Straight-Side Eccentric Geared

Capacities 200-3000 U.S. tons

Features:

- Bed Sizes to 20'

- Recirculating lubrication with

broken line detection and bearing heat sensors

- Hydraulic overload under-slide

connections

- Pneumatic and Hydro-pneumatic die

cushions

- High thermal capacity pneumatic

and hydraulic clutch/brakes

- Straight or T-Track rolling

bolsters

- Partial or complete quick-change

die systems

- Programmable controls

|

|

For enquiries, Contact GW Technologies

here.

|